pH

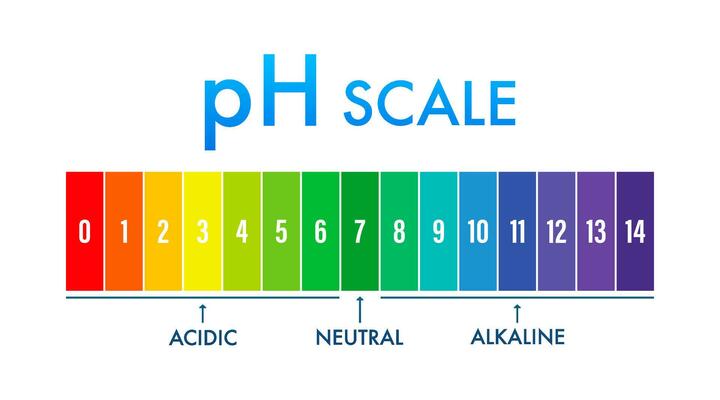

pH is a scale that measures how acidic or alkaline (basic) a solution is. It ranges from 0 to 14, where 7 is neutral — like pure water. Values below 7 indicate acidity (like lemon juice), and values above 7 indicate alkalinity (like baking soda). In the dyeing process, pH is crucial because it affects how well the dye bonds with the fabric, the evenness of the color, and the durability of the dye over time.It’s also very important to control pH in the textile industry because it affects the dyeing process and the safety of the consumer.

Temperature

In dyeing, temperature refers to the heat level applied during the coloring process, which directly impacts how well the dye interacts with the fabric. It controls the rate of dye diffusion, absorption, and fixation. Higher temperatures generally increase molecular movement, helping dyes penetrate fibers more effectively. Different fibers and dyes require specific temperature ranges — for example, polyester often needs high temperatures (around 130°C) for disperse dyes, while cotton works best at lower temperatures (60-80°C) with reactive dyes. Managing temperature properly ensures even coloring, prevents fiber damage, and improves the durability of the final product.

Role of pH and Temperature in the Dyeing Process

Dyeing is a critical stage in textile manufacturing, involving the application of color to fibers, yarns, or fabrics. The quality, vibrancy, and longevity of the dyed material depend on several factors, two of the most important being pH and temperature. Understanding how these elements influence the dyeing process helps ensure consistency and high-quality results.

Importance of pH in the Dyeing Process

pH, which measures the acidity or alkalinity of a solution, plays a vital role in dye absorption and fixation. The pH scale ranges from 0 to 14, with 7 being neutral. Values below 7 indicate acidic conditions, while those above 7 are alkaline. In the dyeing process, the optimal pH level varies based on the type of dye and fiber used.

For instance, acid dyes are typically used for protein-based fibers like wool and silk, requiring an acidic pH environment (around 4-6) for proper dye uptake. In contrast, reactive dyes used on cellulose fibers like cotton work best in an alkaline environment (pH 10-11). Maintaining the right pH ensures that the dye molecules bond effectively with the fibers, producing even coloration and reducing the risk of fading or bleeding.

pH also affects the ionic nature of both the dye and the fiber. At inappropriate pH levels, the fiber’s surface charge may repel dye molecules, leading to poor absorption and uneven dyeing. Moreover, pH influences the stability of the dye solution. An overly acidic or alkaline environment can cause some dyes to decompose or precipitate, diminishing their effectiveness.

Additionally, the pH level impacts post-dyeing processes like washing and finishing. A proper pH balance ensures that the dye remains fixed to the fabric and prevents issues like color bleeding during laundering. Therefore, careful monitoring and adjustment of pH at every stage are crucial for maintaining dye quality and consistency.

Role of Temperature in the Dyeing Process

Temperature is equally crucial in controlling the rate of dye diffusion and fixation. Different dyes and fibers require specific temperature ranges for optimal results. High temperatures typically increase molecular movement, enhancing the penetration of dye into the fiber structure.

For synthetic fibers like polyester, disperse dyes are used at high temperatures (130°C) to facilitate dye sublimation and absorption. Conversely, natural fibers like cotton often require lower temperatures (60-80°C) with reactive dyes to prevent fiber damage while ensuring adequate fixation.

Temperature also influences the reaction speed between dye and fiber. For reactive dyes, a higher temperature accelerates the chemical bond formation, improving dye fixation. However, excessive heat can cause dye degradation or lead to uneven dyeing due to rapid dye uptake.

Moreover, temperature control is vital in maintaining the physical integrity of the fabric. Excessive heat can cause shrinkage or weakening of fibers, while insufficient heat may lead to incomplete dye absorption. This delicate balance makes temperature management a key aspect of the dyeing process.

Interplay of pH and Temperature

The synergy between pH and temperature determines the overall success of the dyeing process. Even if one parameter is optimized, an imbalance in the other can lead to subpar results. For example, maintaining an appropriate pH at the wrong temperature may result in incomplete dye fixation or fabric damage.

Certain dyes require specific pH and temperature conditions simultaneously to achieve optimal results. For instance, in the case of reactive dyes, an alkaline pH combined with a moderate temperature facilitates the formation of covalent bonds between the dye and the fiber. Similarly, acid dyes require both a low pH and controlled heat for effective coloration.

Consistent monitoring and adjustment of pH and temperature are essential in industrial dyeing to achieve vibrant, long-lasting colors. Advanced techniques, such as computer-controlled dyeing systems, help regulate these variables, ensuring reproducible quality and reducing waste.

Conclusion

The role of pH and temperature in the dyeing process cannot be overstated. Proper control of these factors enhances dye absorption, ensures even coloration, and improves the durability of the dyed material. By understanding the delicate balance between pH and temperature, manufacturers can achieve high-quality textile products that meet industry standards and consumer expectations.

Furthermore, innovations in dyeing technology, such as eco-friendly dyes and automated pH and temperature control systems, are revolutionizing the industry. These advancements not only improve efficiency but also contribute to sustainable practices by reducing water and energy consumption. As the textile sector continues to evolve, maintaining optimal pH and temperature will remain essential for producing vibrant, durable, and environmentally responsible products.