Woven fabrics form the backbone of the global textile industry, from everyday apparel to technical and industrial textiles. At the heart of every woven fabric lies a simple yet highly engineered structure created by the interlacement of warp yarns and weft yarns. Understanding the difference between warp and weft is essential for textile students, professionals, designers, and manufacturers alike, as these two yarn systems directly influence fabric strength, appearance, performance, and end-use.

This article provides an in-depth comparison of warp vs weft yarns in woven fabrics, covering their definitions, characteristics, manufacturing roles, and impact on fabric properties.

What Are Warp Yarns?

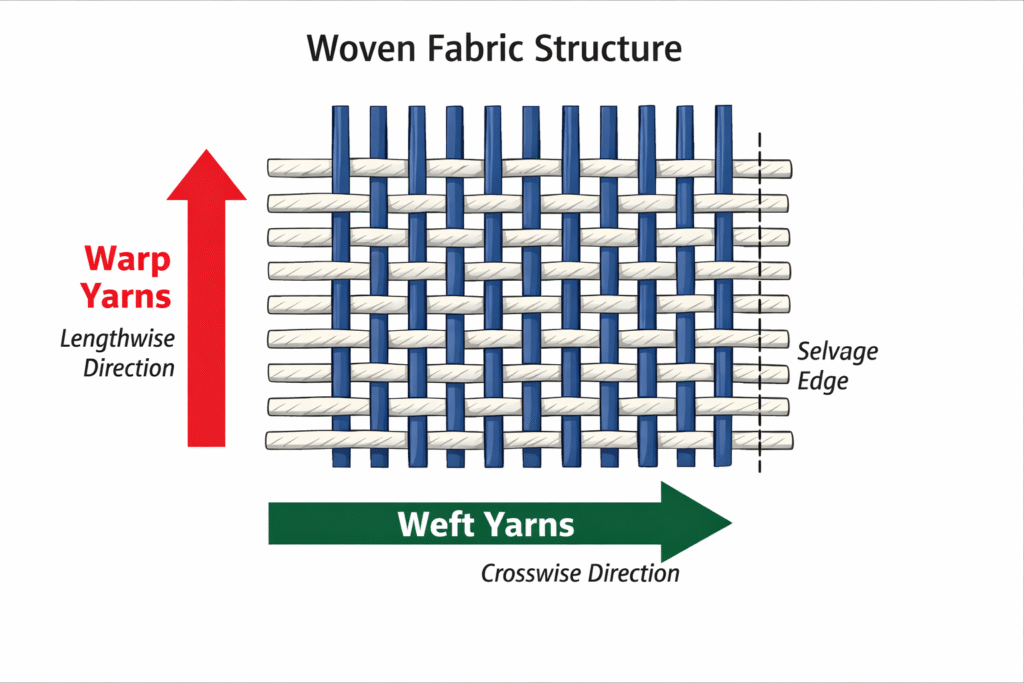

Warp yarns are the set of yarns that run lengthwise in a woven fabric, parallel to the fabric selvage. These yarns are held under tension on the loom during weaving and form the backbone of the fabric structure.

Key Characteristics of Warp Yarns

Warp yarns are engineered to withstand significant mechanical stress during weaving. As they are constantly stretched, lifted, and lowered, they must possess higher strength and abrasion resistance.

Key features include:

Oriented in the fabric length direction

Usually stronger and smoother than weft yarns

Subjected to high tension during weaving

Typically sized (coated with sizing chemicals) to reduce breakage

Contribute significantly to fabric strength and dimensional stability

Because of these requirements, warp yarns often use higher twist levels or stronger fiber blends.

What Are Weft Yarns?

Weft yarns (also called filling yarns or pick yarns) are inserted horizontally, perpendicular to the warp yarns. Unlike warp yarns, weft yarns are not held under constant tension and are inserted across the fabric width using a shuttle, rapier, air jet, or water jet.

Key Characteristics of Weft Yarns

Weft yarns play a major role in fabric aesthetics and comfort. Since they experience less mechanical stress during weaving, they can be softer and bulkier.

Typical features include:

Oriented in the fabric width direction

Lower tension compared to warp yarns

Generally softer, thicker, and less twisted

Rarely sized

Strongly influence fabric handle, drape, and appearance

Weft yarns allow designers more freedom in selecting yarn types, colors, and textures.

Warp vs Weft: Structural Differences

The structural differences between warp and weft yarns define how woven fabrics behave in real-life use.

Direction and Orientation

Warp yarns run parallel to the selvage and determine fabric length

Weft yarns run from one selvage to the other and determine fabric width

This orientation affects how fabric stretches, shrinks, and reacts to stress.

Differences in Yarn Preparation

Warp Yarn Preparation

Warp yarns undergo extensive preparation before weaving:

Warping – arranging yarns in parallel order

Sizing – applying protective chemicals (starch, PVA, CMC)

Beaming – winding warp yarns onto the loom beam

Sizing improves:

Tensile strength

Abrasion resistance

Weaving efficiency

Weft Yarn Preparation

Weft yarns require minimal preparation:

Wound onto packages or pirns

No sizing in most cases

Focus on uniformity and appearance rather than strength

Impact on Fabric Properties

Strength and Durability

Warp yarns contribute more to tensile strength

Weft yarns contribute to tear resistance and flexibility

Fabrics generally exhibit higher strength along the warp direction.

Fabric Appearance

Warp yarns often define fabric surface smoothness

Weft yarns influence color patterns, stripes, and textures

In many fabrics, decorative effects are achieved by changing weft yarn colors or counts.

Shrinkage Behavior

Warp yarns shrink less due to higher tension and sizing

Weft yarns shrink more, especially in natural fibers like cotton

This is why fabrics often shrink more in width than length.

Comfort and Drape

Weft yarns largely control softness and drape

Warp yarns provide structure and shape retention

Balanced fabrics carefully optimize both systems.

Warp and Weft Density (Ends and Picks)

Fabric construction is often defined by:

Ends per inch (EPI) – number of warp yarns per inch

Picks per inch (PPI) – number of weft yarns per inch

Higher EPI:

Increases fabric strength

Improves abrasion resistance

Higher PPI:

Improves cover

Enhances fabric fullness

The ratio of EPI to PPI plays a crucial role in fabric balance.

Warp vs Weft in Different Fabric Types

Plain Weave

Equal interlacement of warp and weft

Balanced appearance

Similar influence from both yarn systems

Twill Weave

Warp or weft dominance creates diagonal lines

Warp-faced twills are stronger and smoother

Weft-faced twills are softer and heavier

Satin Weave

Long warp or weft floats

Warp satin: smoother surface

Weft satin: softer drape

Common Fibers Used in Warp and Weft

Warp yarns often use:

Polyester

High-twist cotton

Blended yarns

Weft yarns often use:

Cotton

Viscose

Modal

Specialty textured yarns

This combination balances performance and comfort.

Practical Identification of Warp and Weft

In finished fabrics, warp and weft can be identified by:

Selvage direction (warp runs parallel)

Higher yarn density (usually warp)

Less stretch in warp direction

Smoother yarns in warp direction

Conclusion

The distinction between warp and weft yarns in woven fabrics goes far beyond simple orientation. Warp yarns provide strength, stability, and durability, while weft yarns enhance comfort, appearance, and design flexibility. A successful woven fabric depends on the intelligent balance between these two yarn systems.

For textile engineers, designers, and manufacturers, understanding warp and weft behavior is fundamental to fabric development, quality control, and end-use performance. Whether designing apparel, home textiles, or technical fabrics, mastering warp and weft principles leads to better, more functional woven products.